Process control for the agricultural world

Automate your feed mill, flour mill,

premix plants, and more !

As a leader in North America, Matissoft makes the optimized management of your plant with minimal human intervention a possibility, so you can benefit from process automation and control of your operations from anywhere. The Matissoft software does not only manage the fabrication process, it manages everything from the raw materials and inventory, to the event and ingredients traceability, to the management of contamination, cleaning and delivery, etc.

By choosing our solutions, you gain a process control and data acquisition (SCADA) system that is completely integrated to a manufacturing execution system (MES), adapted to your needs

From a control room or

a remote workstation!

Whatever the type of facilities and their size, your production plants will be managed individually, yet also linked together: feed mill, flour mill, premix plant, grain and trans-shipment center, fertilizer center, wood pellets, manufacturer of food or products for small animals (pet food).

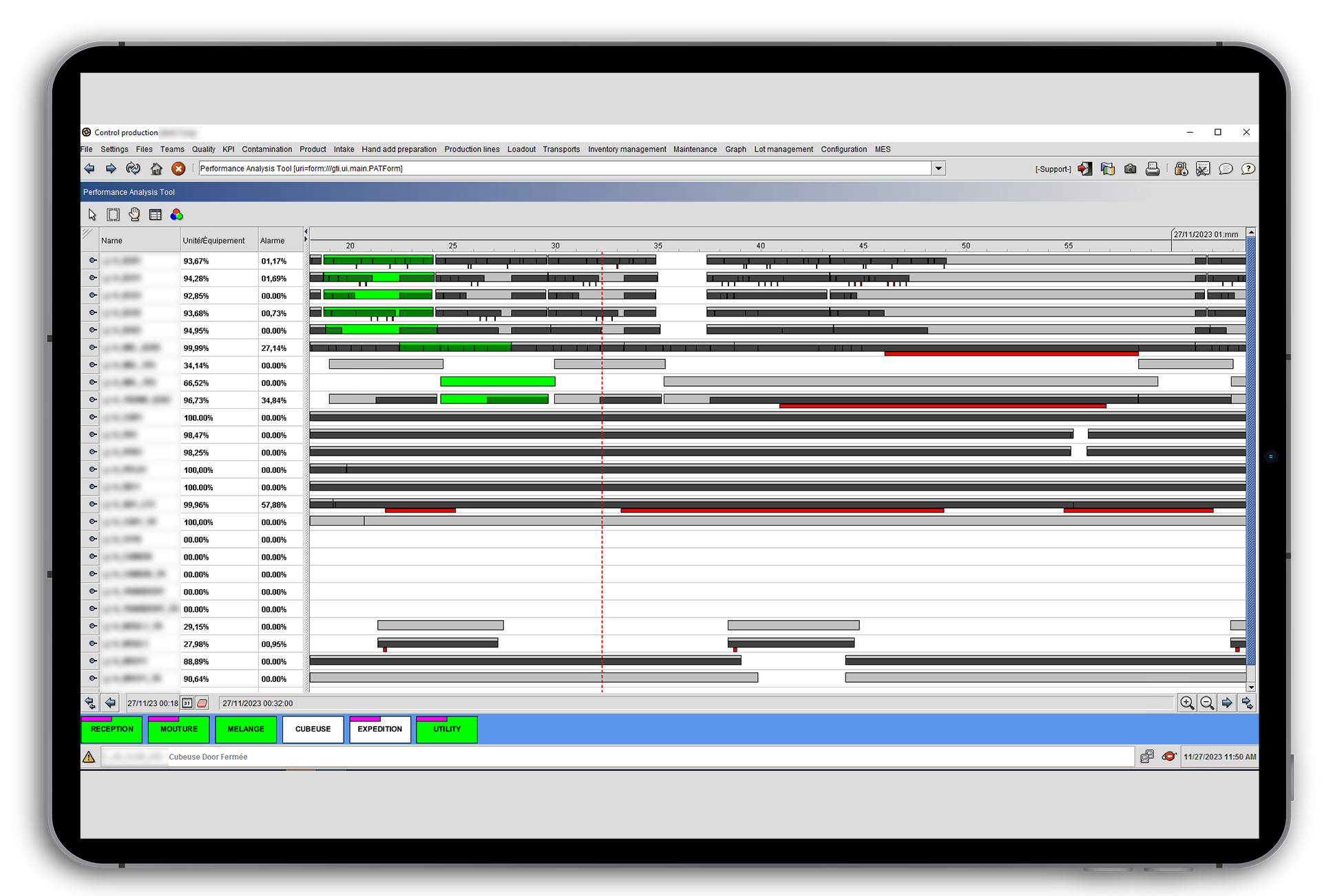

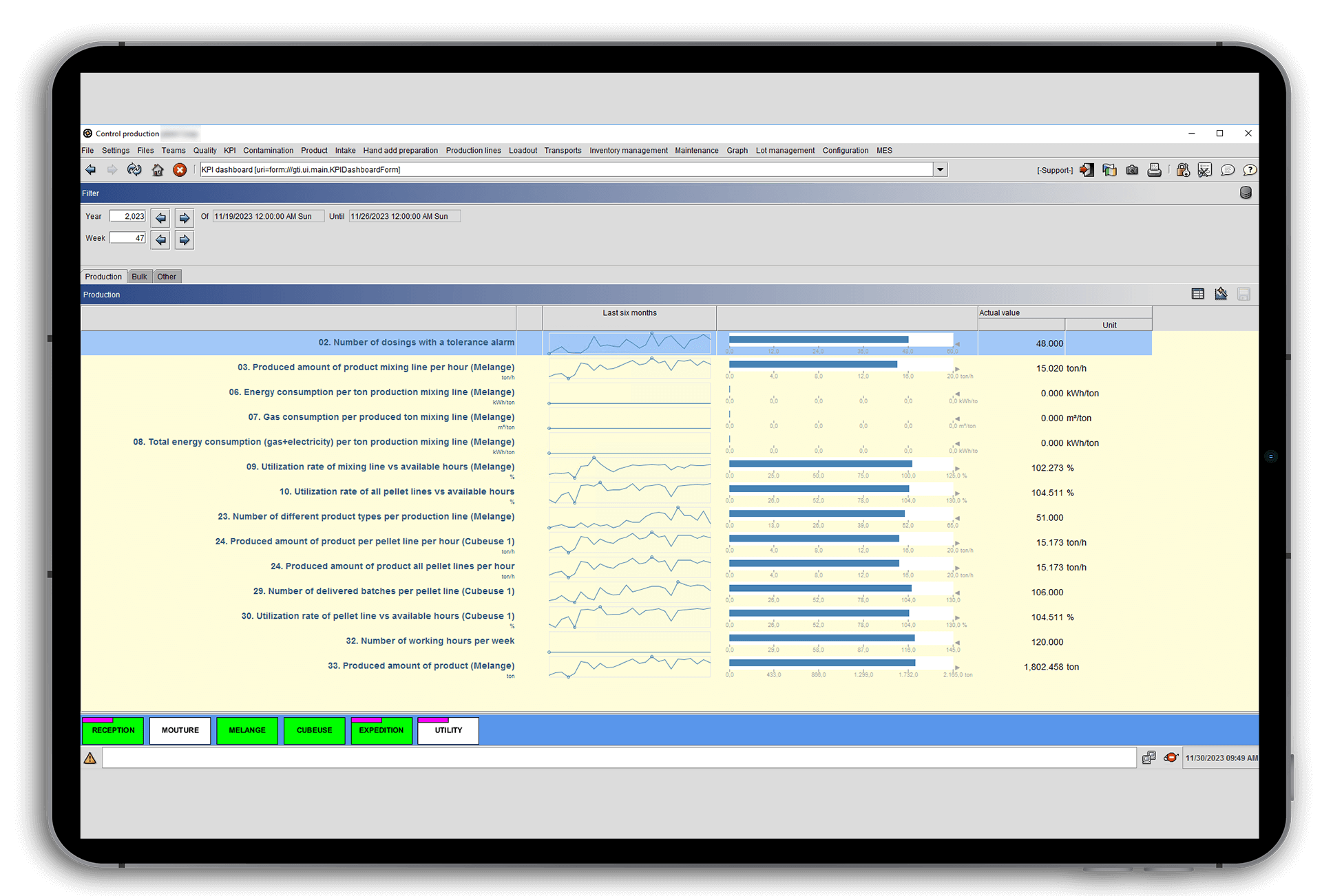

Performance analysis

In one simple click, access all fundamental information in real time or history, to make informed decisions. Obtain a graphical analysis of your plant’s performance (for the last 24 hours).

Turnkey service

Enjoy entirely personalized service: project management, engineering and supply of materials (power supply, starter box, instrumentation and control, etc.), programming, quick and efficient 24/7 service, and much more!

Complete

traceability

Inventory traceability and history with a list of reminders for manual operations, events, ingredients, end products and system/equipment parameter changes, are available to you at all times.

Uninterrupted

manual control

Authorized personnel can control almost any equipment and/or instrumentation manually at any step of the process, on a production line in automatic mode, thus avoiding production stops.

We take care of

all your operations.

Native functionalities

Performance analysis

-

- Dashboards and key performance indicators (KPIs)

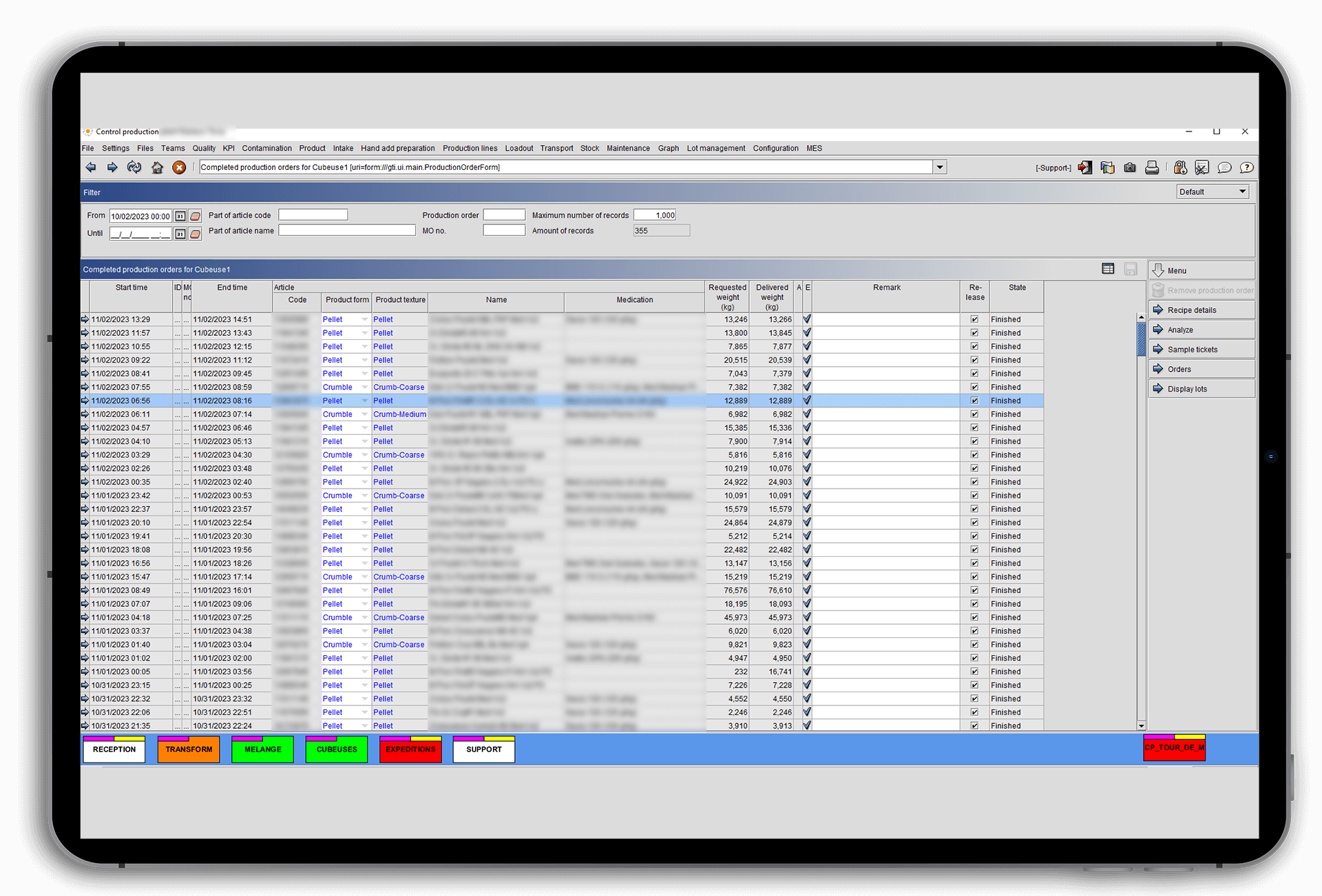

- Multiple production reports

- GANTT chart of production times by system/production line

- Real-time data (trending)

- Data export to Excel or PDF

- Task scheduling for producing reports

Production safety

-

- Safe and smart management of production routes along with production flow

- Production planning and monitoring according to inventory

- Alerts and warnings

- Team or operator management for safety and efficiency

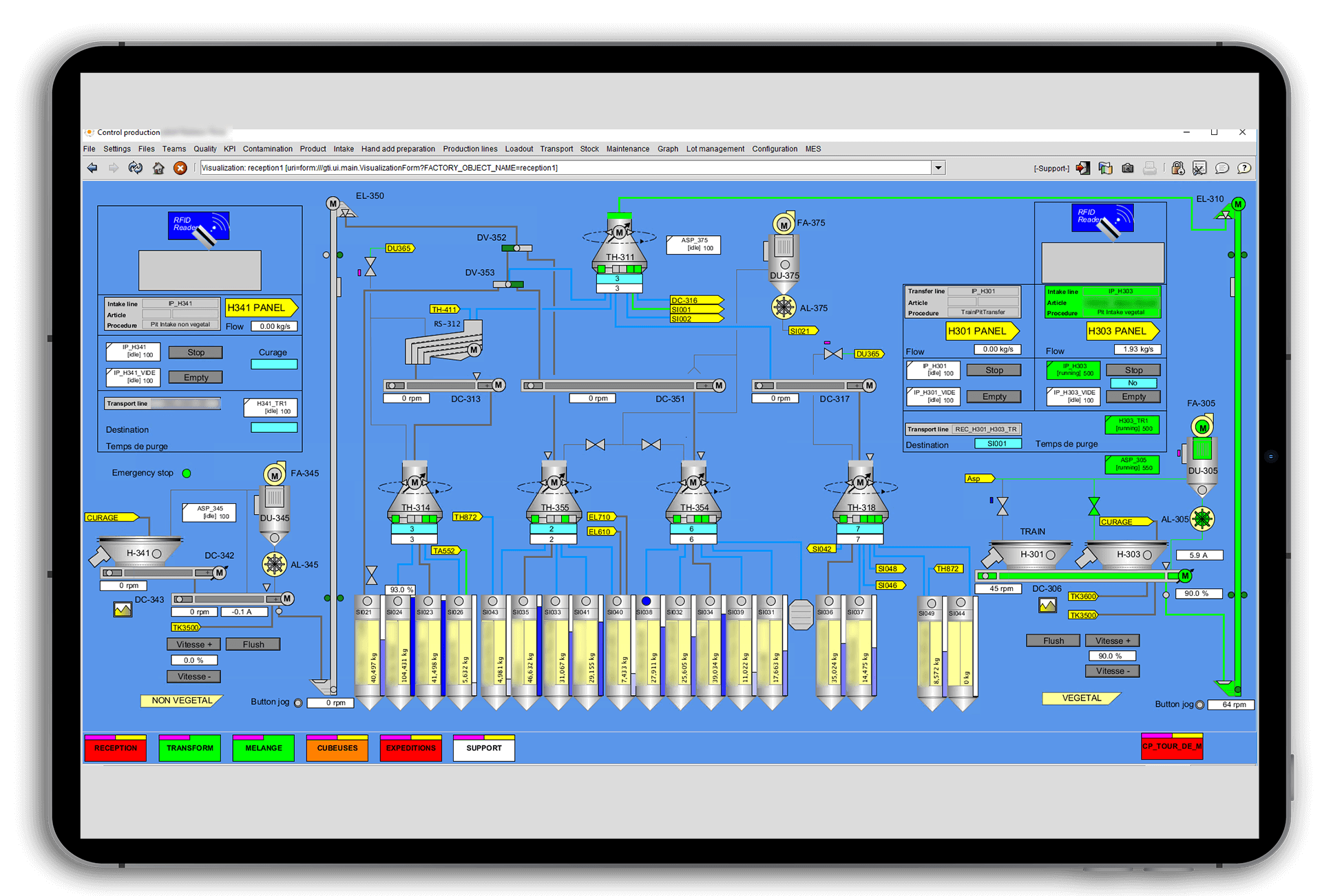

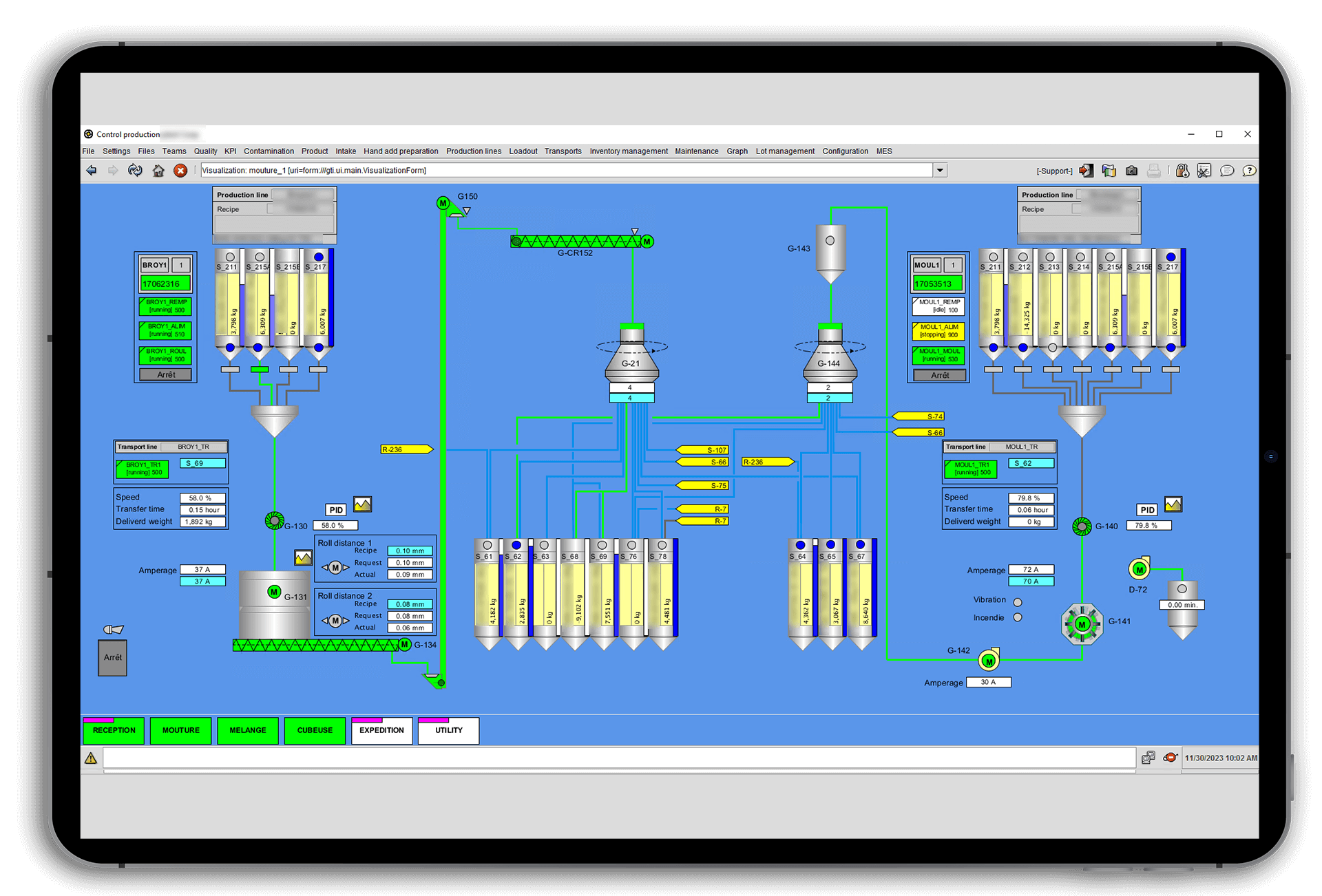

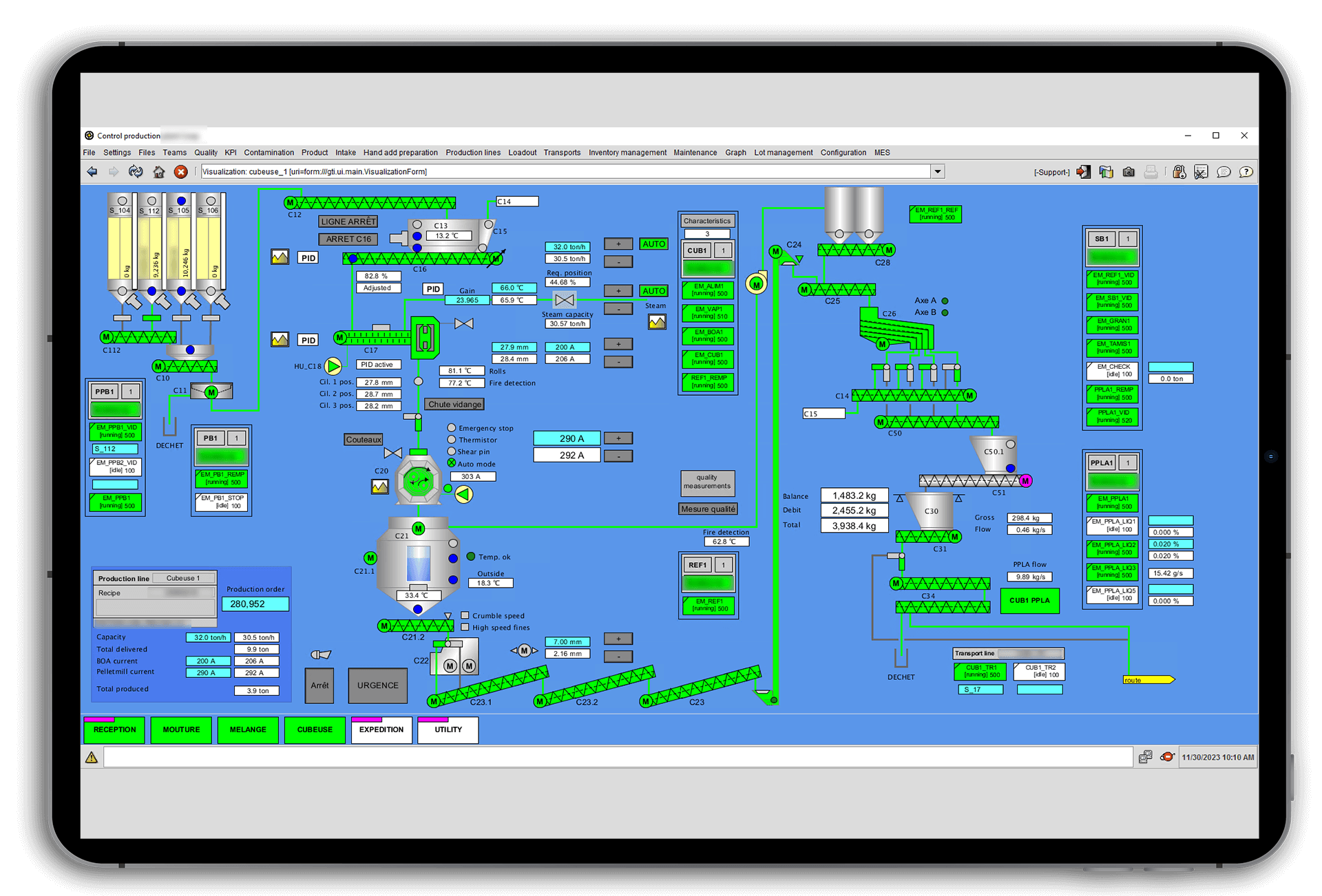

- Graphic display of all plant equipment and signals

- Manual or automatic management of lines or equipments

- Availability of all systems in manual, semi-automatic or entirely automatic mode

- Complete inventory management

- Full traceability of events, ingredients, products and system/equipment parameters

- Management of veterinary prescriptions, contaminations and substitutes

- Creation and management of recipes with revisions

Simplified management

-

- Documentation, training and tech support

- Customizable Wiki to develop your own documentation center

- Standardized programming compliant with ISA 88/95 international standards

- Different systems check, from anywhere

Receiving

- Reception of raw materials, liquid or solid, bagged or in bulk

- Warehouse management

- Automatic and manual system (report, traceability and weighing)

- Sampling and label printing

- Simplified system allowing the operation of the receiving system by the truck drivers.

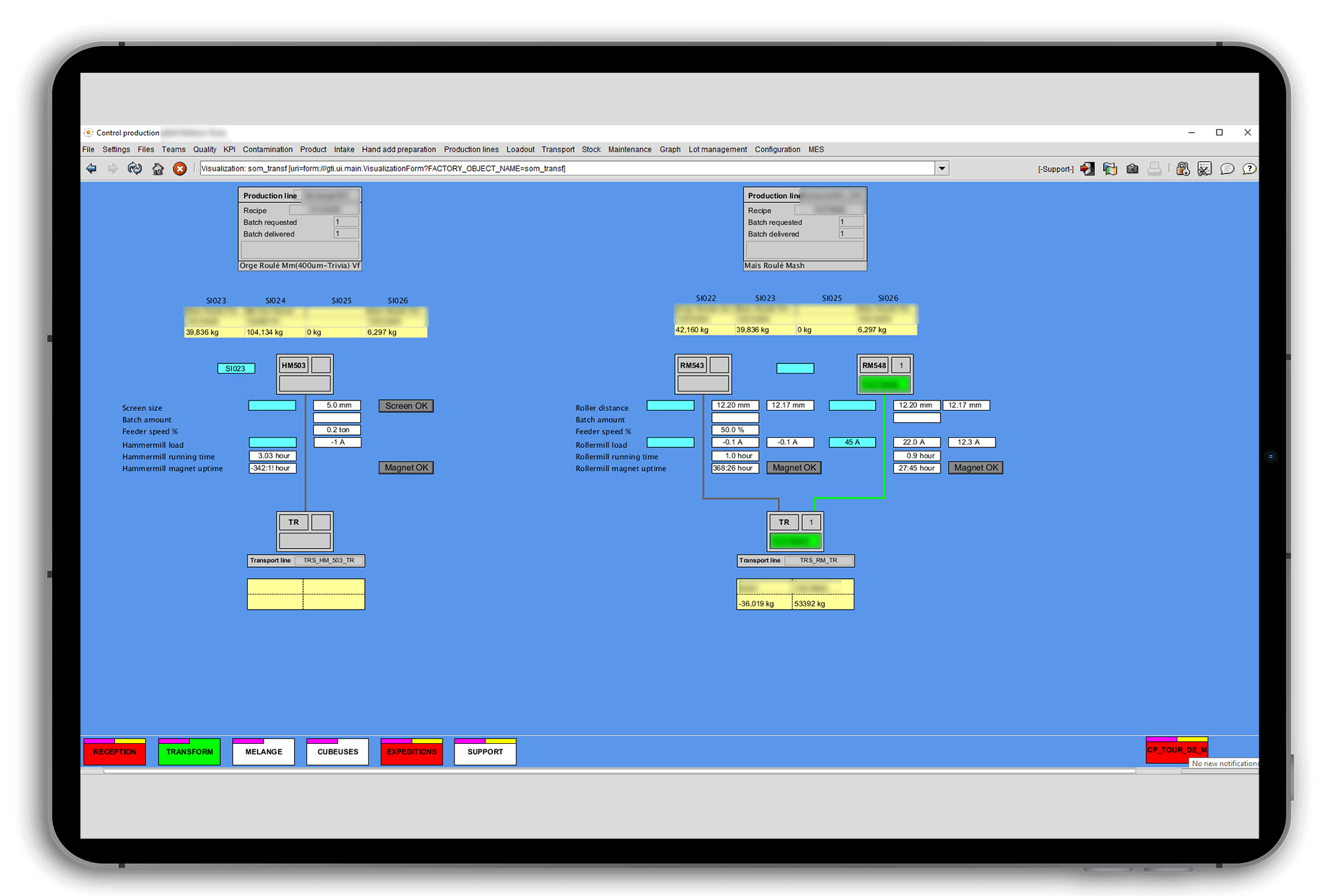

Transformation

- Mixing feed and roller mill system for grain transformation for mixes, or for resale

- Pre- and post-milling

- Automatic production according to inventory levels

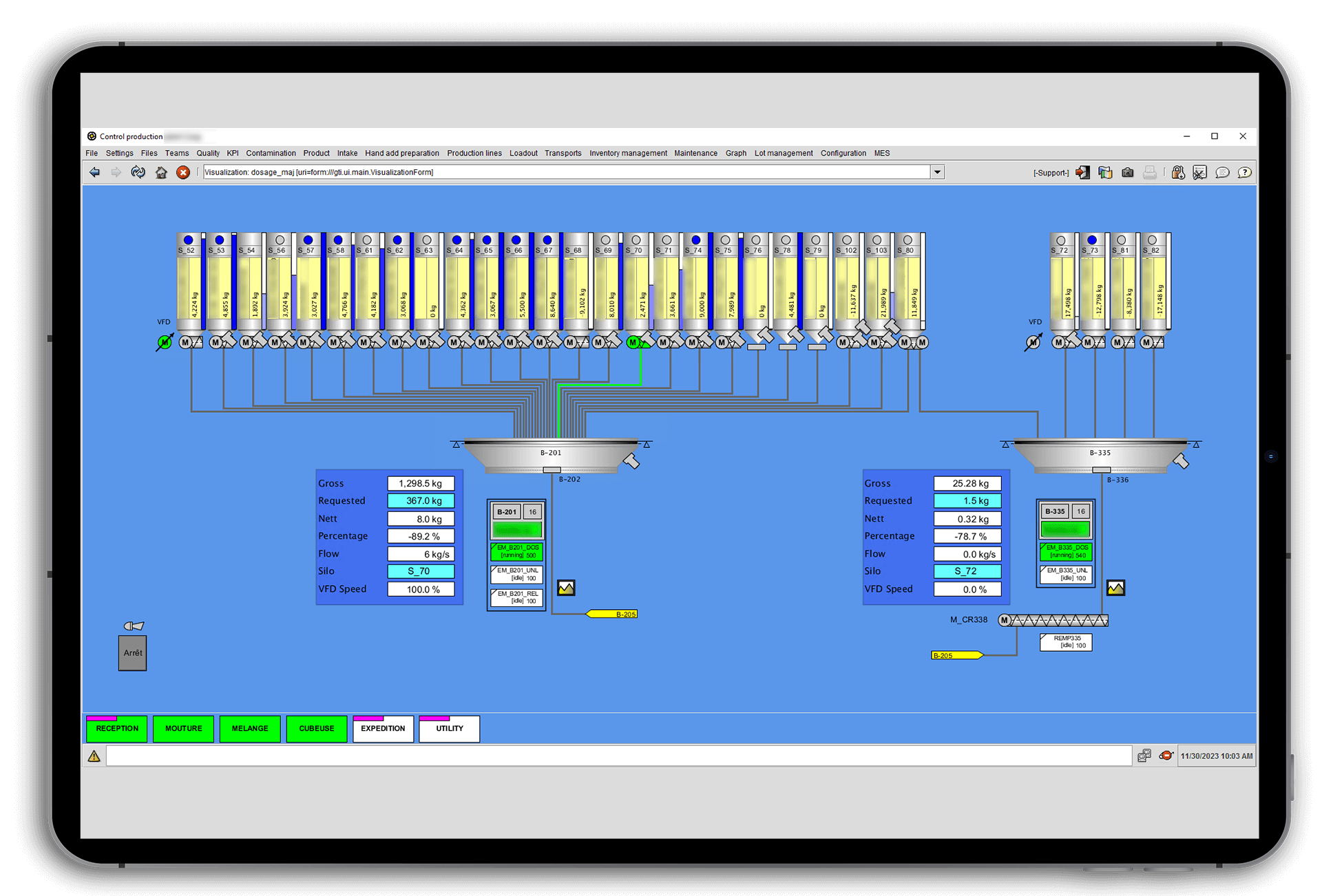

Mixing

- Dosage of solid and liquid ingredients

- Integration of hand adds for recipe production to consequently direct to the following system (dicer, shipping, bagging, etc.)

- Adaptive system for ingredient dosage to optimize desired quantities

- Parameterization of screws to maximize dosage speed

- Rapid batch changes (rebatching)

- Premix management

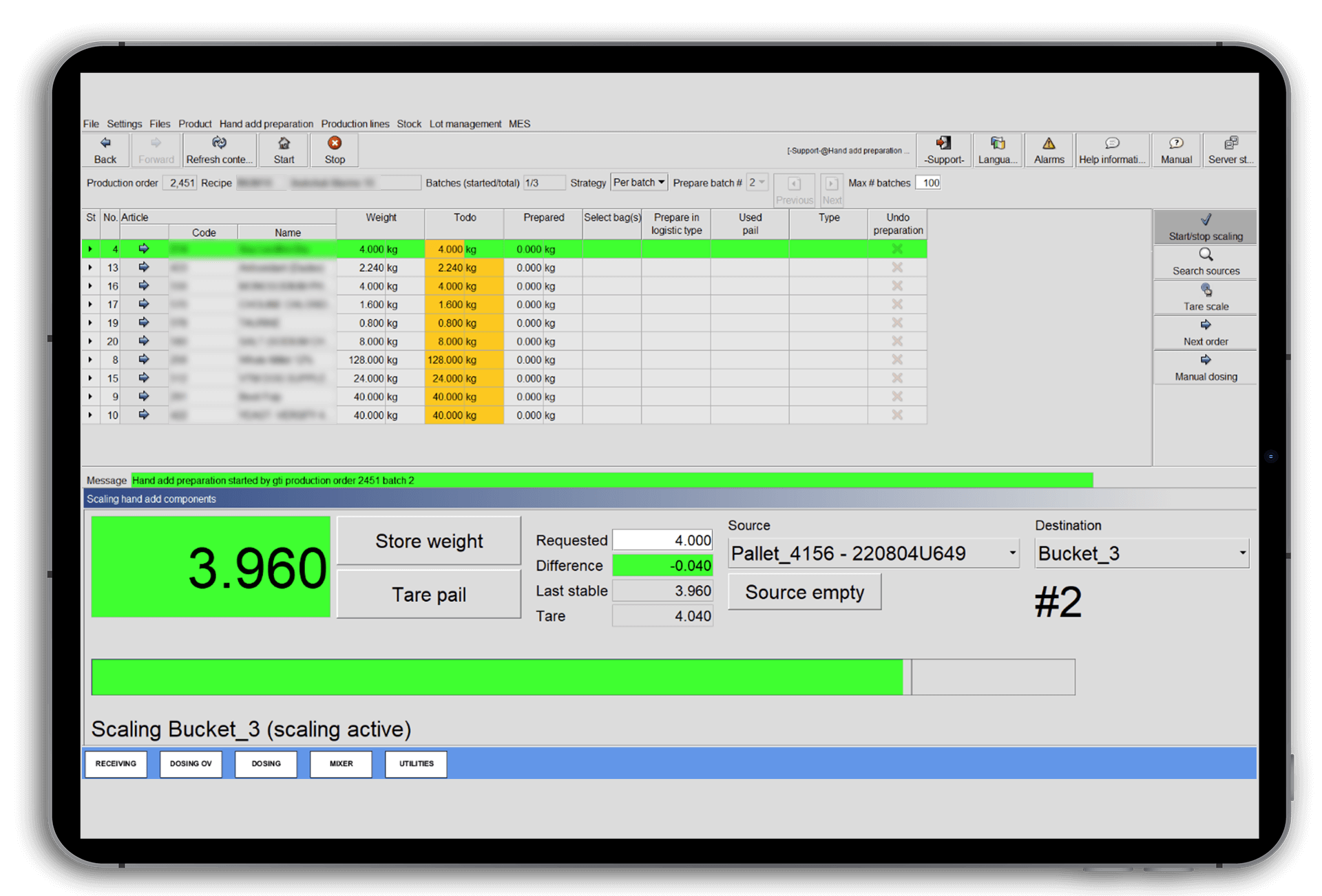

Hand adds:

- Validation of ingredients for manual additions to ensure precise dosage for each product

- Manual dosage for better precision of small quantities

- Integration of barcode scanners for safe management avoiding any contamination

- Validation of addition of manual add-ins to the mixer according to the batch

Pelleting

- Optimized startup (speed and temperature) according to production conditions, equipment and recipe parameters

- Optimal control of the cooler, granulator, sieve, continuous liquid application and product flow

- Expander and Boa management

- Continuous batch production

- Optimization of production according to compatibilities

- Incompatibility management

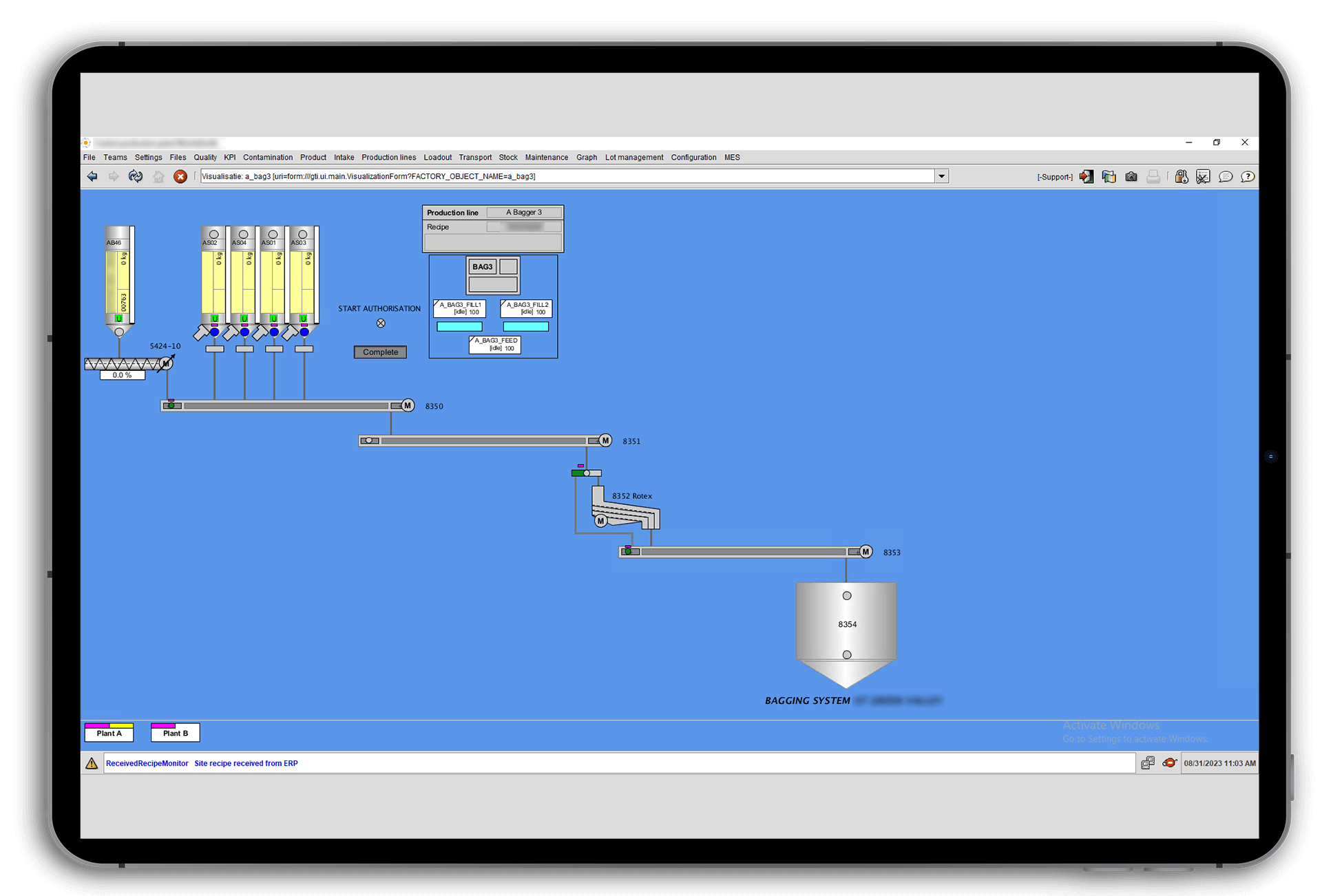

Bagging

- Bagging system interfaced for inventory, warehouse and traceability

- Integration into automated bagging systems

- Inventory according to product format

- Robotization of palletization process

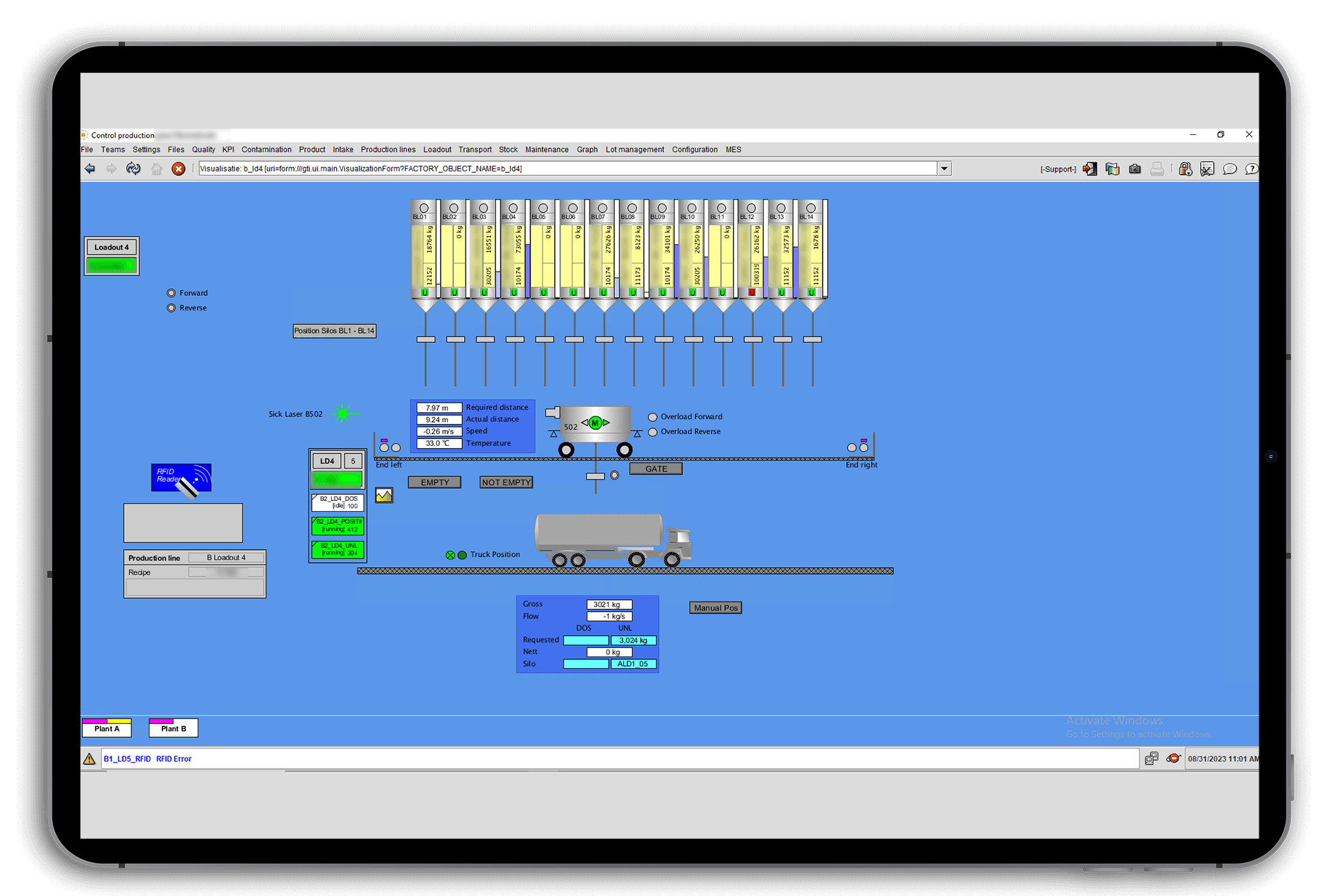

Load-out

- Bulk product load-out thanks to a manual, semi-automatic or completely automated system

- Self-loading by truck driver

- Packing list printing with guaranteed analysis

- Sampling and label printing

- Possible connection to our transport management system

- High-speed loading system with mobile scale

Automated transactions allow us to save a great amount of time by avoiding tedious manual entries. Management reports make everyday decision-making easier. The implementation was very smooth. Whenever I have requests for any modifications, Matissoft’s after-sales service is quick and simple. The difference is like night and day in comparison to my experience with our previous solution.

General manager