The only ERP solution

created for the agricultural world

Are you considering investing in an ERP solution (Enterprise Resource Planning)? Put your trust in Matissoft, the only ERP developed specifically for the agricultural world. Whatever your area of specialization (milling, grain center, pet food, farming, hatchery, premix plant, fertilization center, litter, etc.), you will finally have peace of mind and save time thanks to our software. A true world-class ERP, adapted to your reality.

Why choose our agro ERP?

Our Matissoft ERP’s integrated management software package stands above all other ERPs on the market; finance, business management, maintenance and data warehouse, integrated with the specialized modules of your market sector, will simplify your tasks while adding to your performance.

Evolving ERP

Benefit from a constantly evolving technology.

Agricultural Expertise

Contributing our expertise to the agro world since 1995.

World-renowned Technology

The best agricultural technologies, serving your operations.

An ERP to maximize visibility

on your agricultural operations

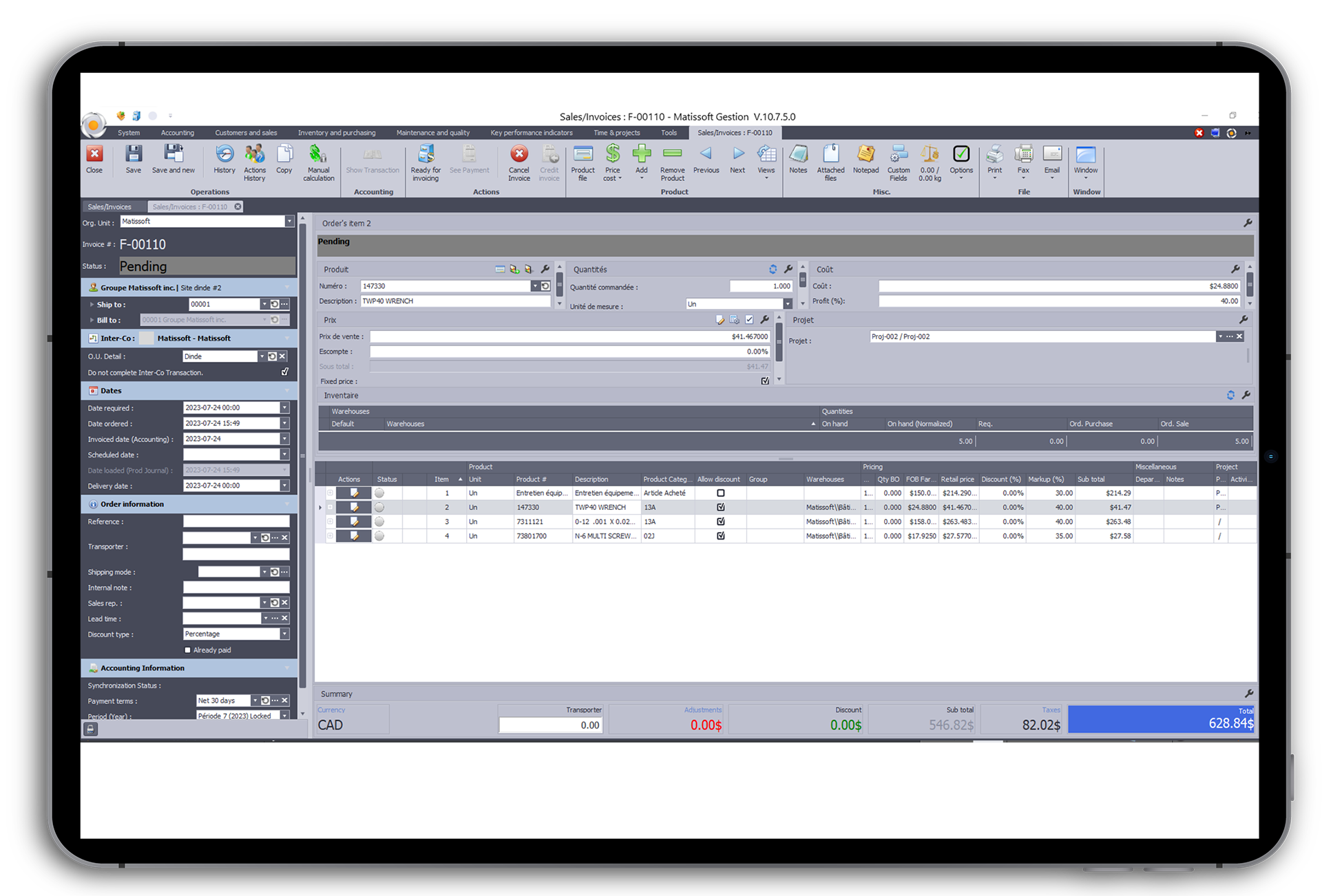

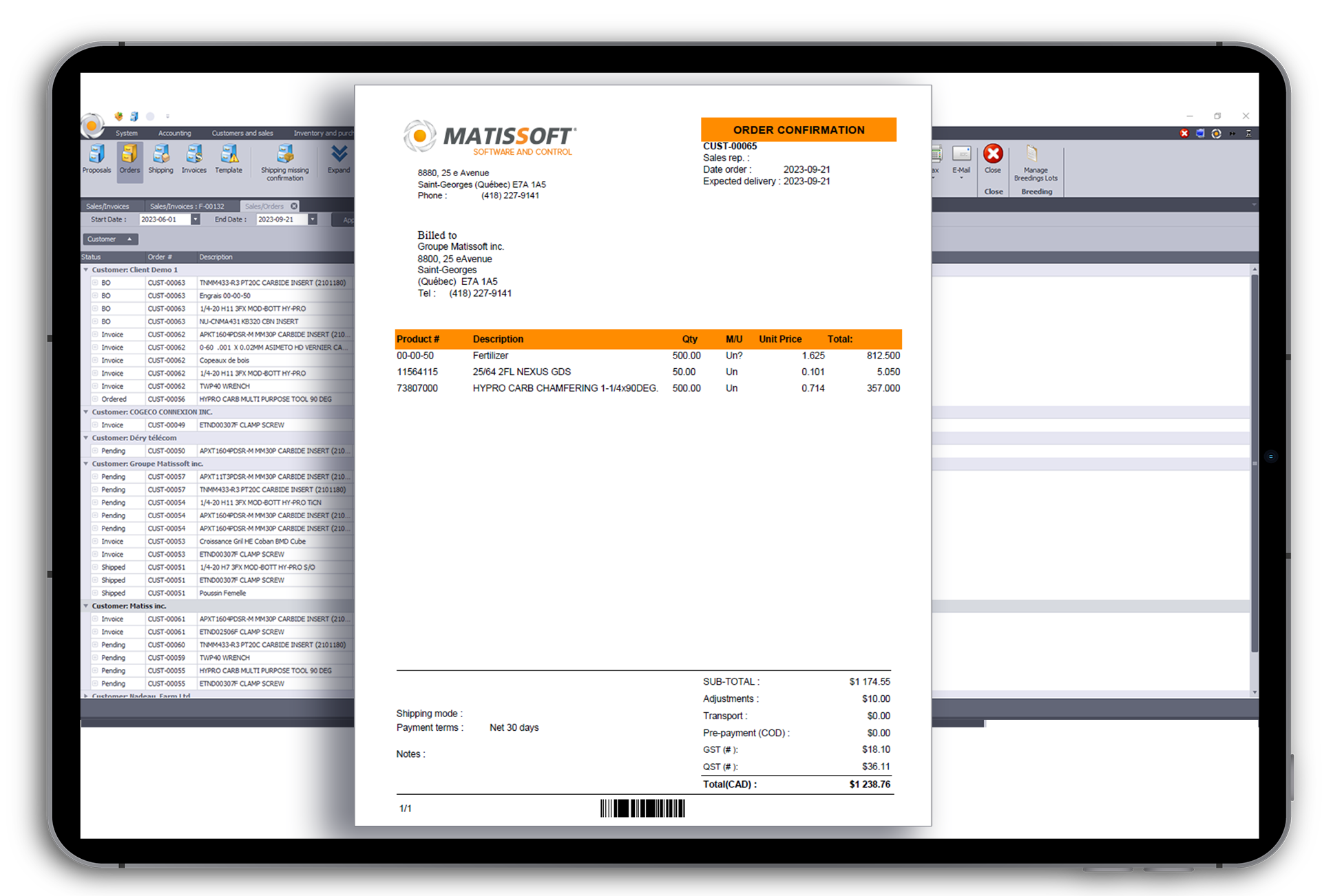

With our completely integrated ERP system that is specialized for your sector, you will be able to accomplish your tasks efficiently while optimizing the daily operations of your business. Your operations will be 100% managed, from quotes to collection, along with a complete supply process. You will have a comprehensive view of each step of your administrative process, in addition to specific functionalities that are entirely scalable and adapted to your agricultural reality.

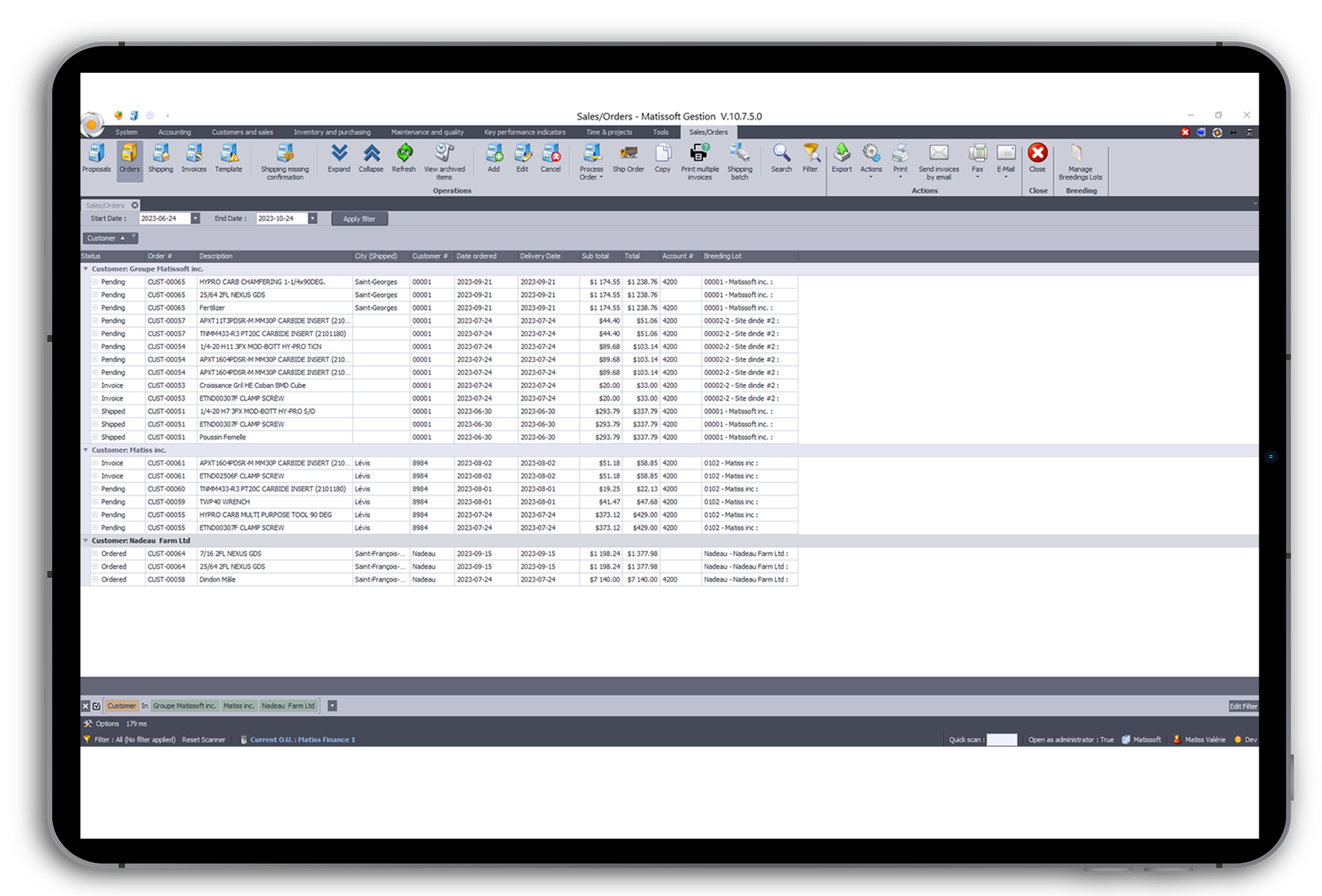

Sales Module

In addition to the complete sales process, we have integrated these functionalities that are specific to the agricultural sector:

- Automatic generation of price lists linked to the fluctuations in the purchase cost of grains

- Recipe management from formulation software

- Validation of veterinary prescriptions upon order

- Application of active recipes upon order (feed recipe)

- Automatic processing of slaughter reports and egg-grading reports

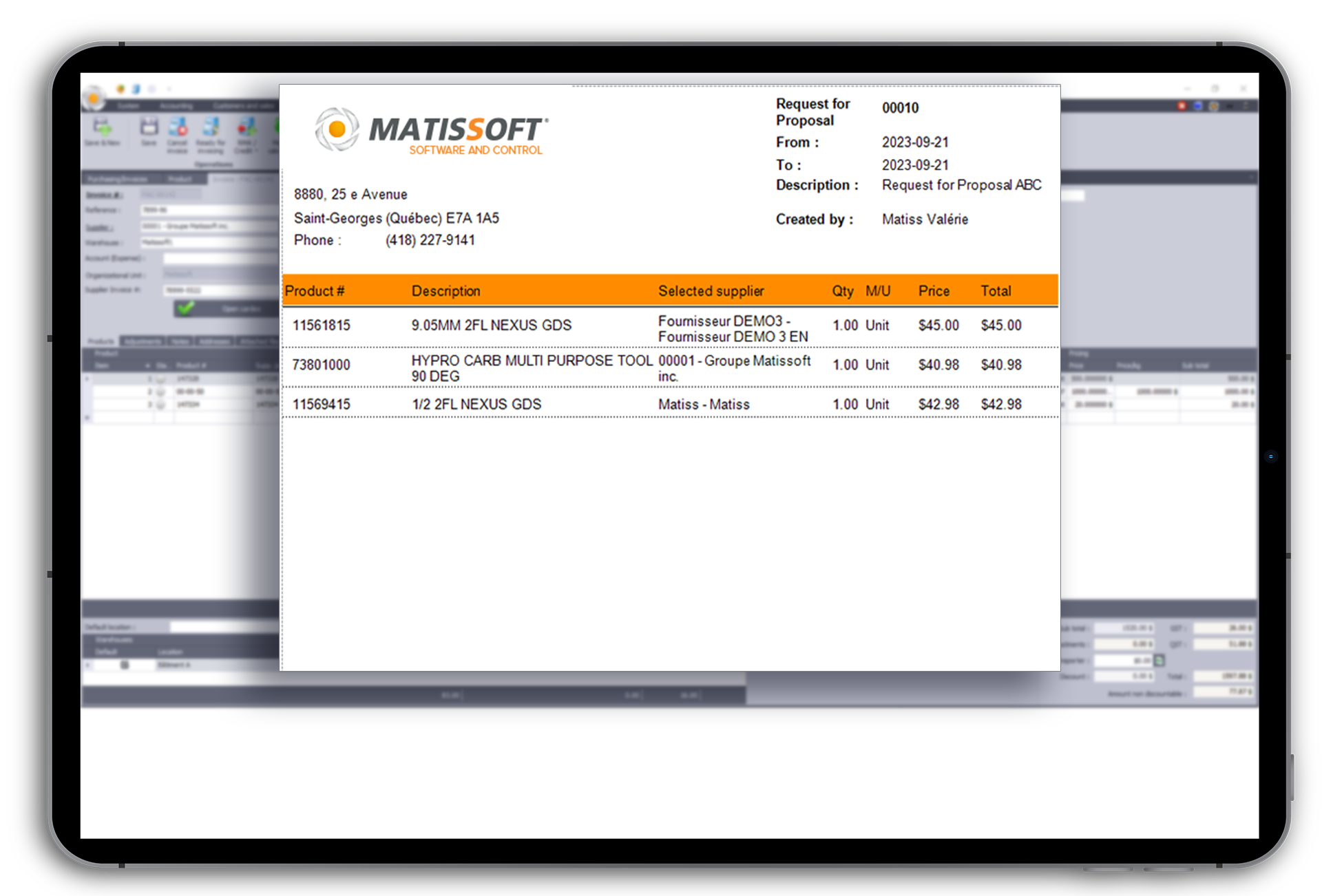

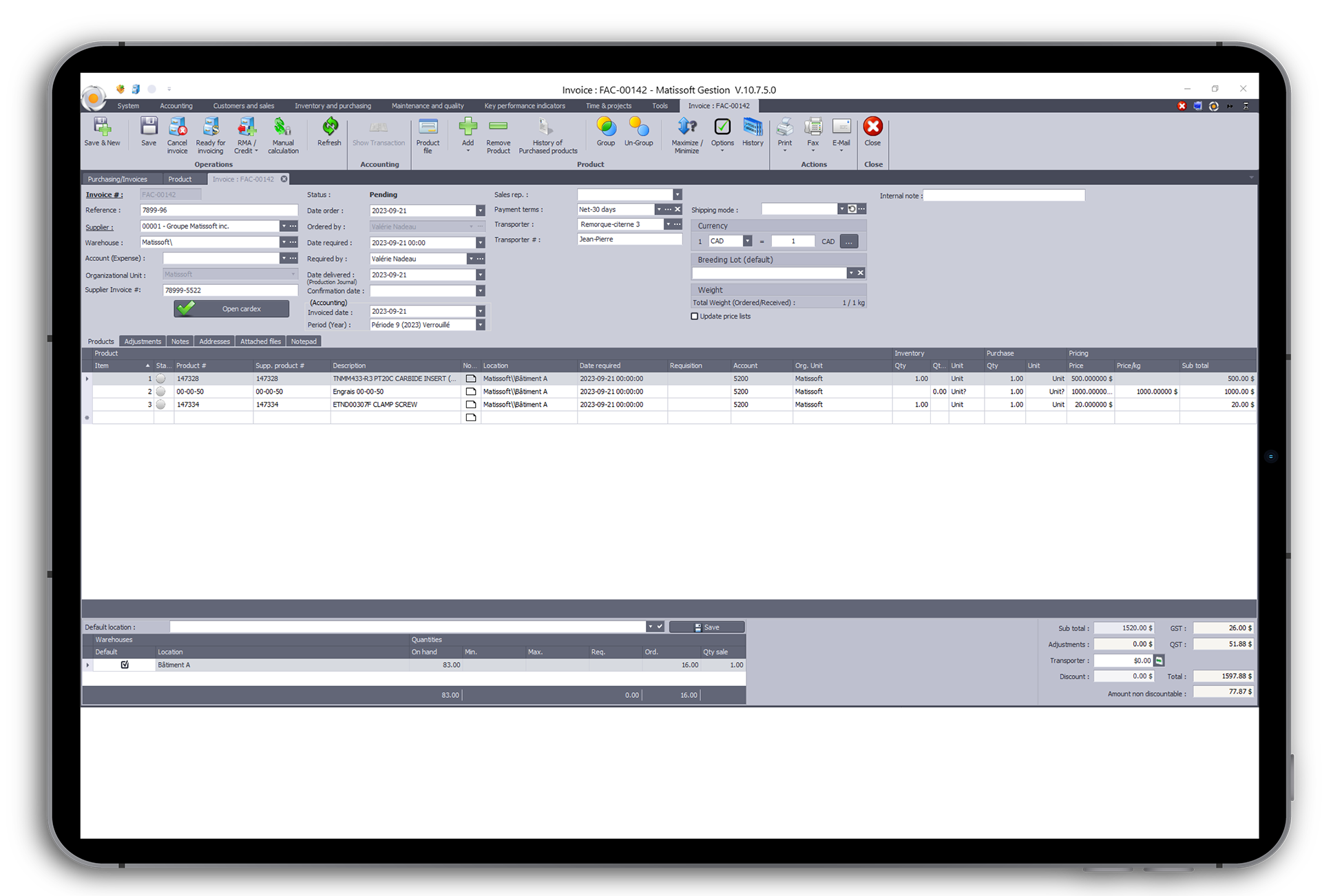

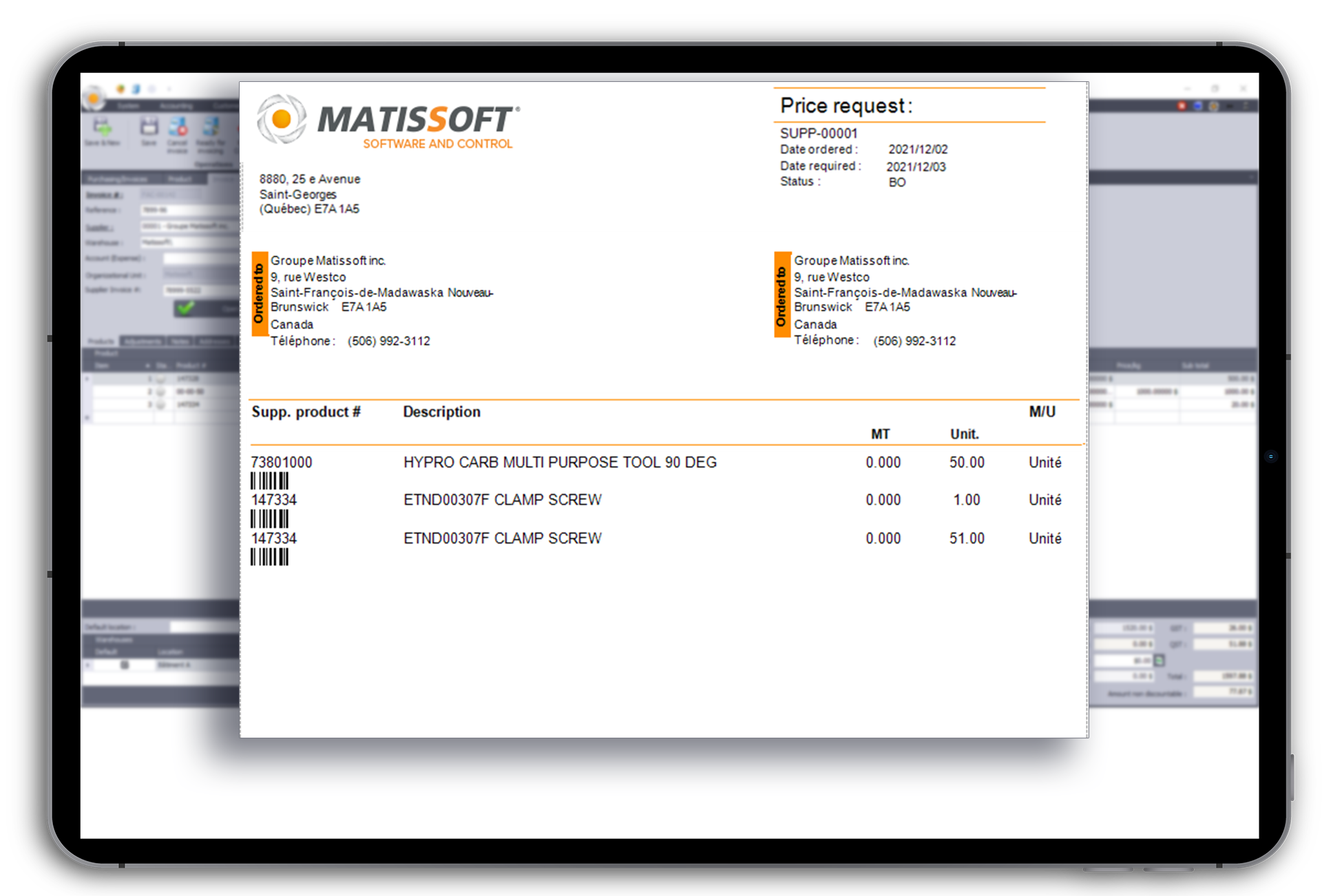

Supply Module

This module follows the usual ERP process for purchases, while also offering these typically agricultural functionalities:

- Pesticide management

- Purchase agreement, ex : grains contract or purchase of chicks

- Product expiry monitoring

- Purchase by lot monitoring

Each intercompany transaction is automatically processed, with no double entries.

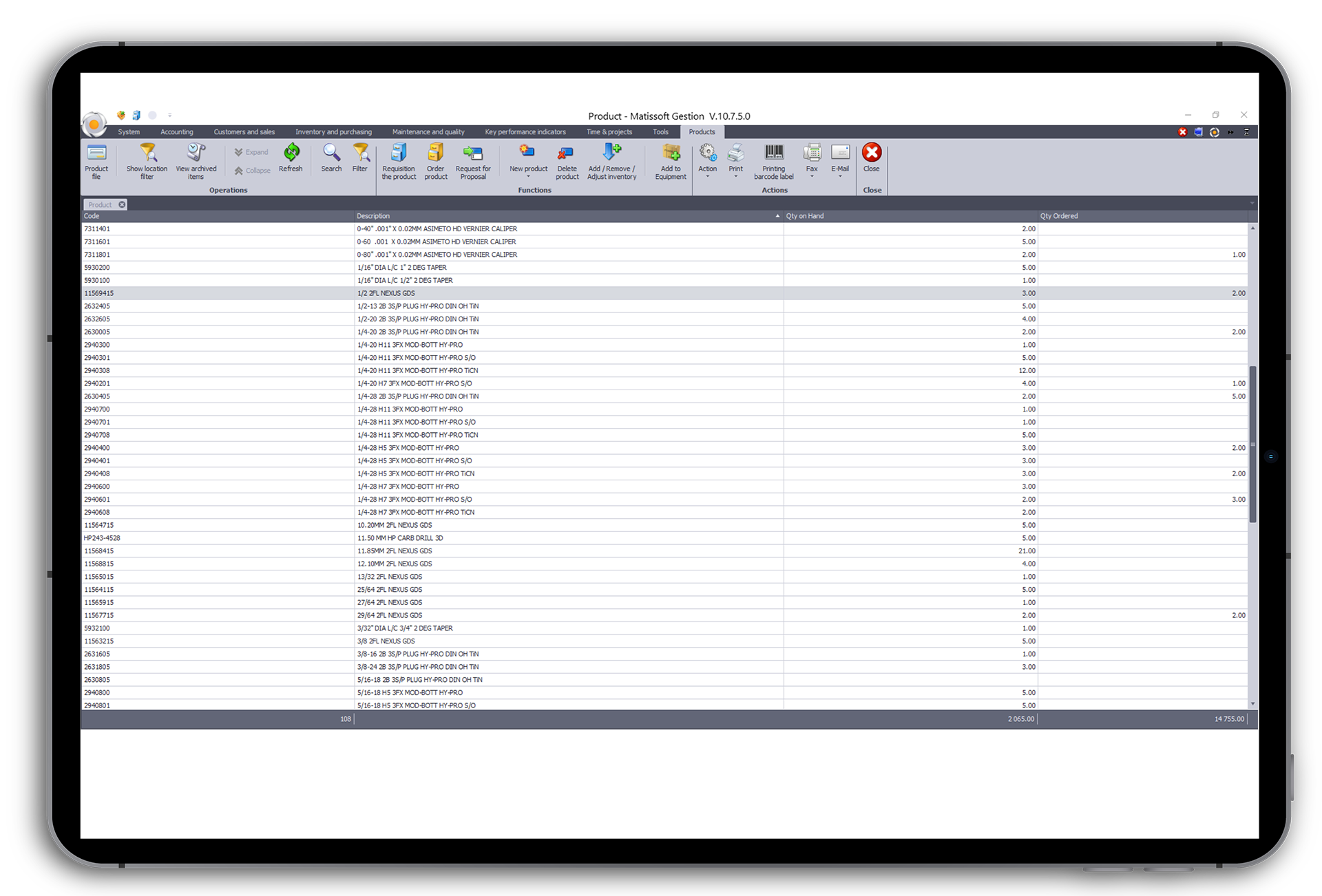

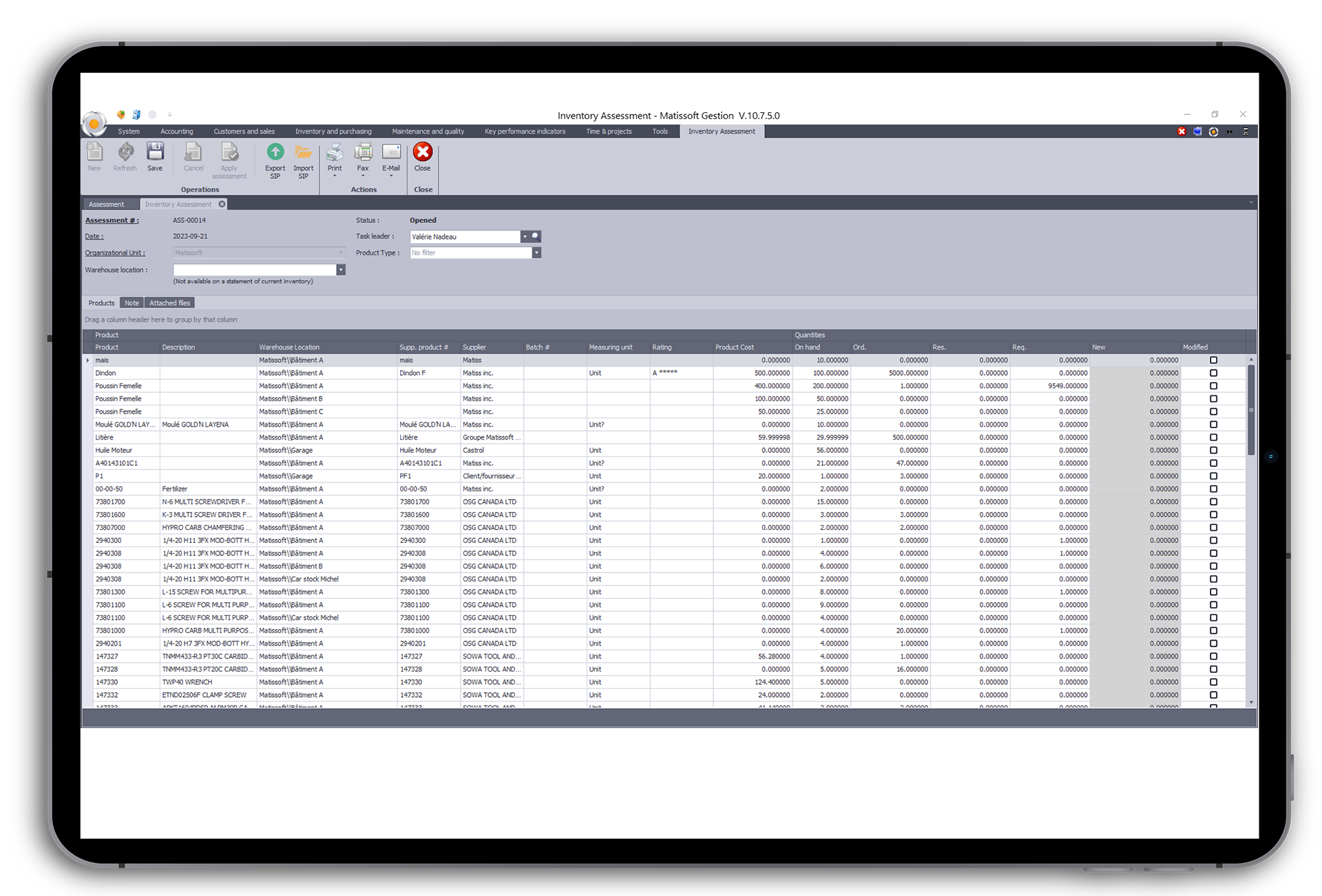

Inventory Module

You will also have multisite inventory monitoring, in real time, allowing you to ensure:

- Hardware management (point of sale/cash drawer)

- Grain consignment (cardex)

- Inventory management per silo

- Bar code stock management

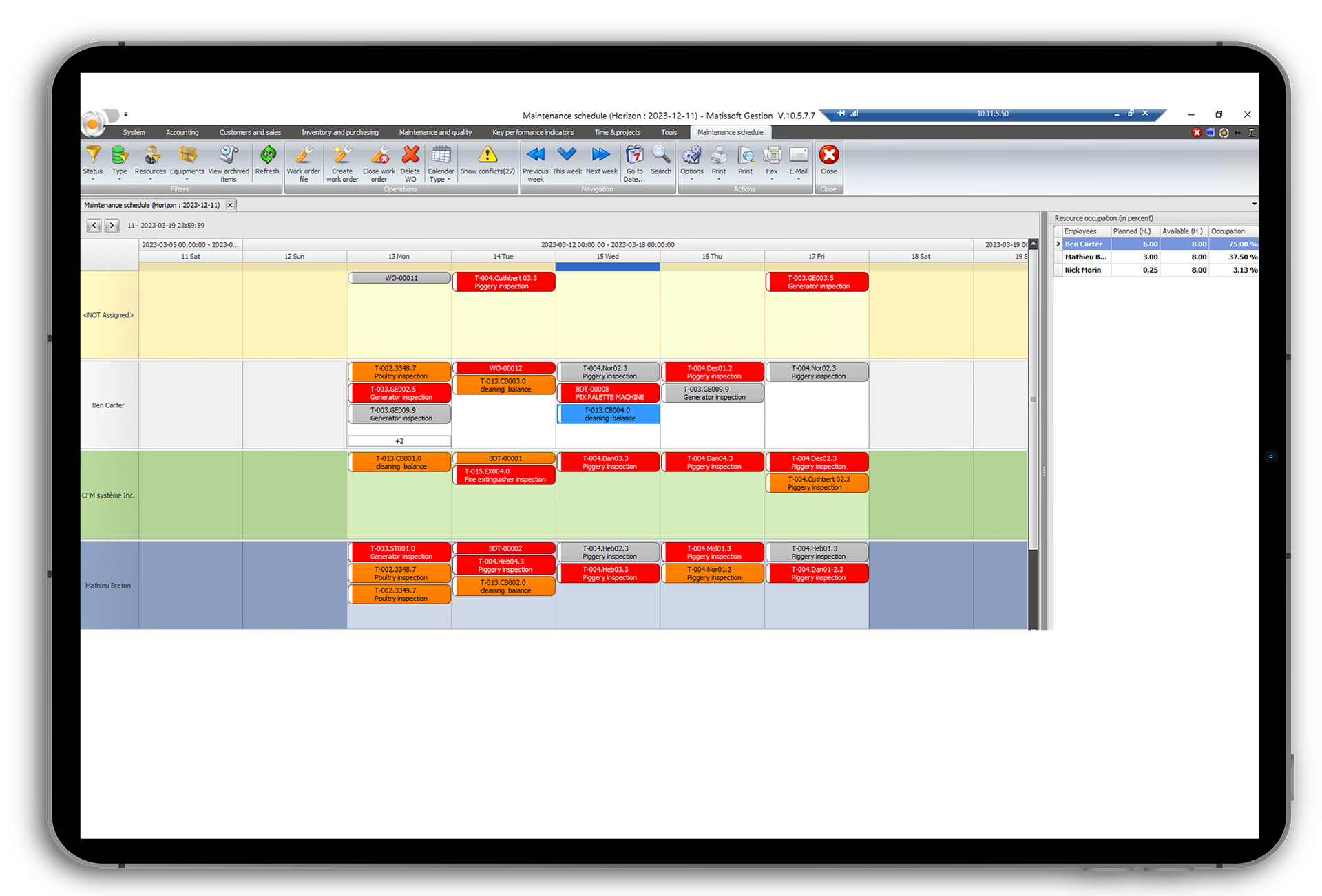

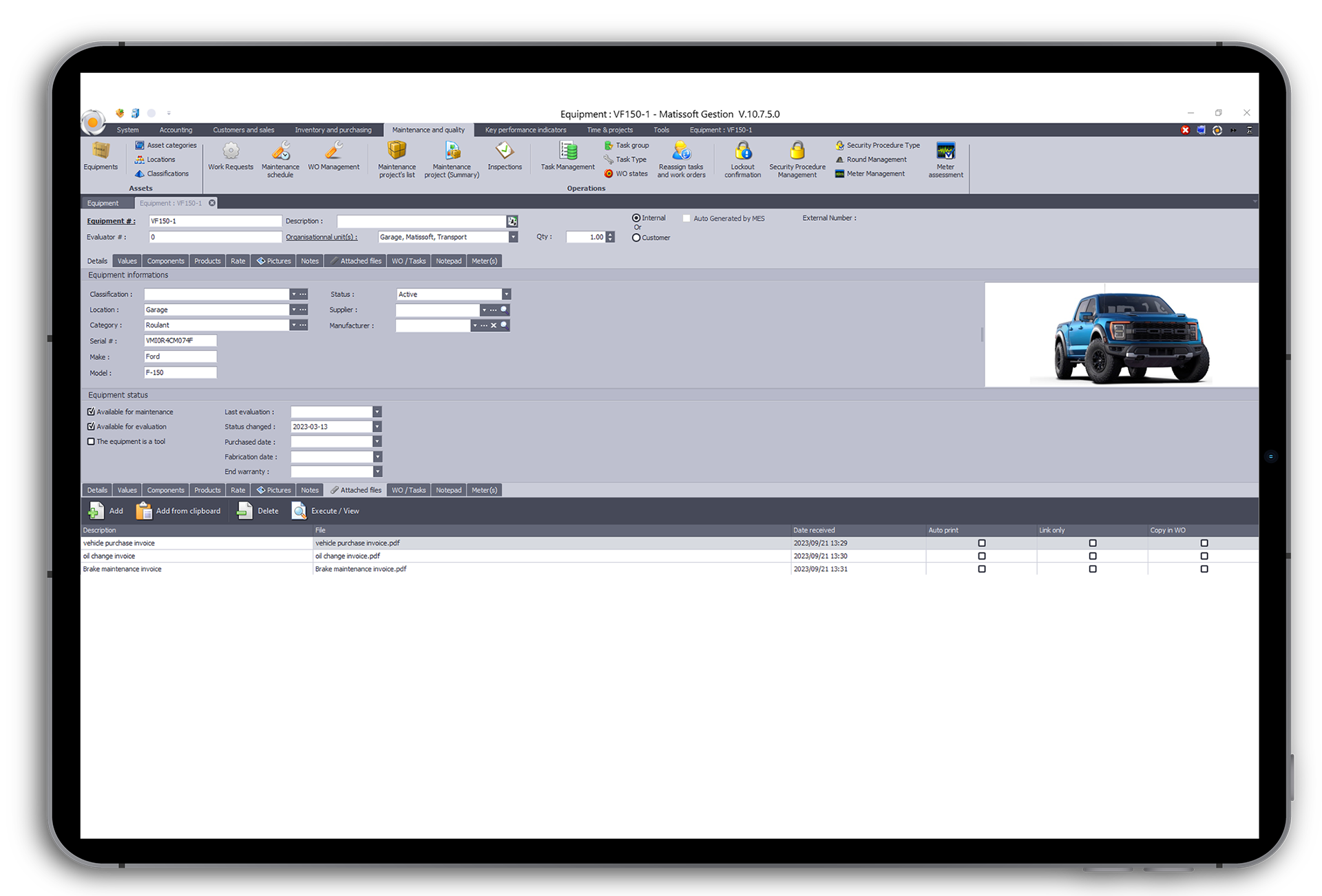

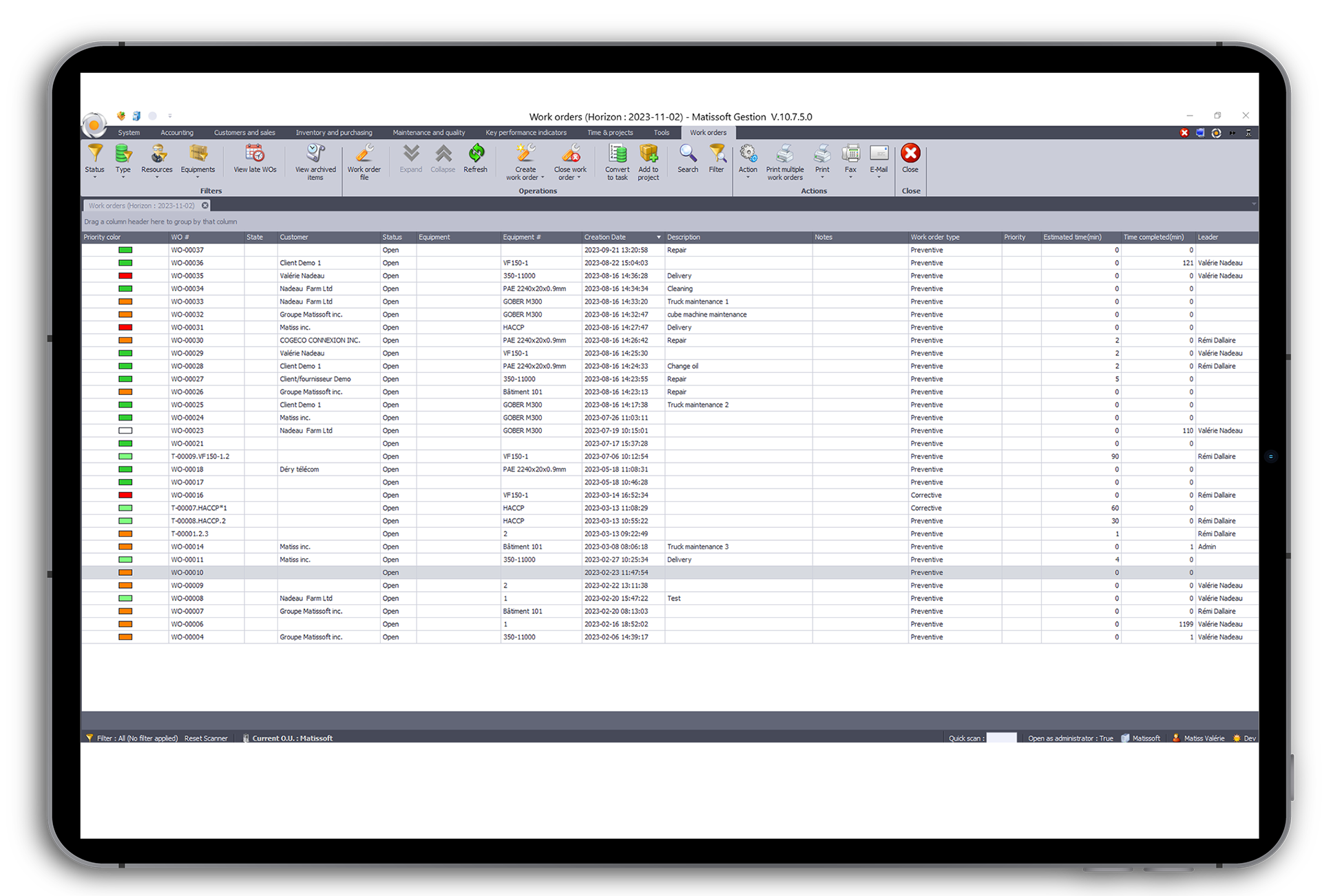

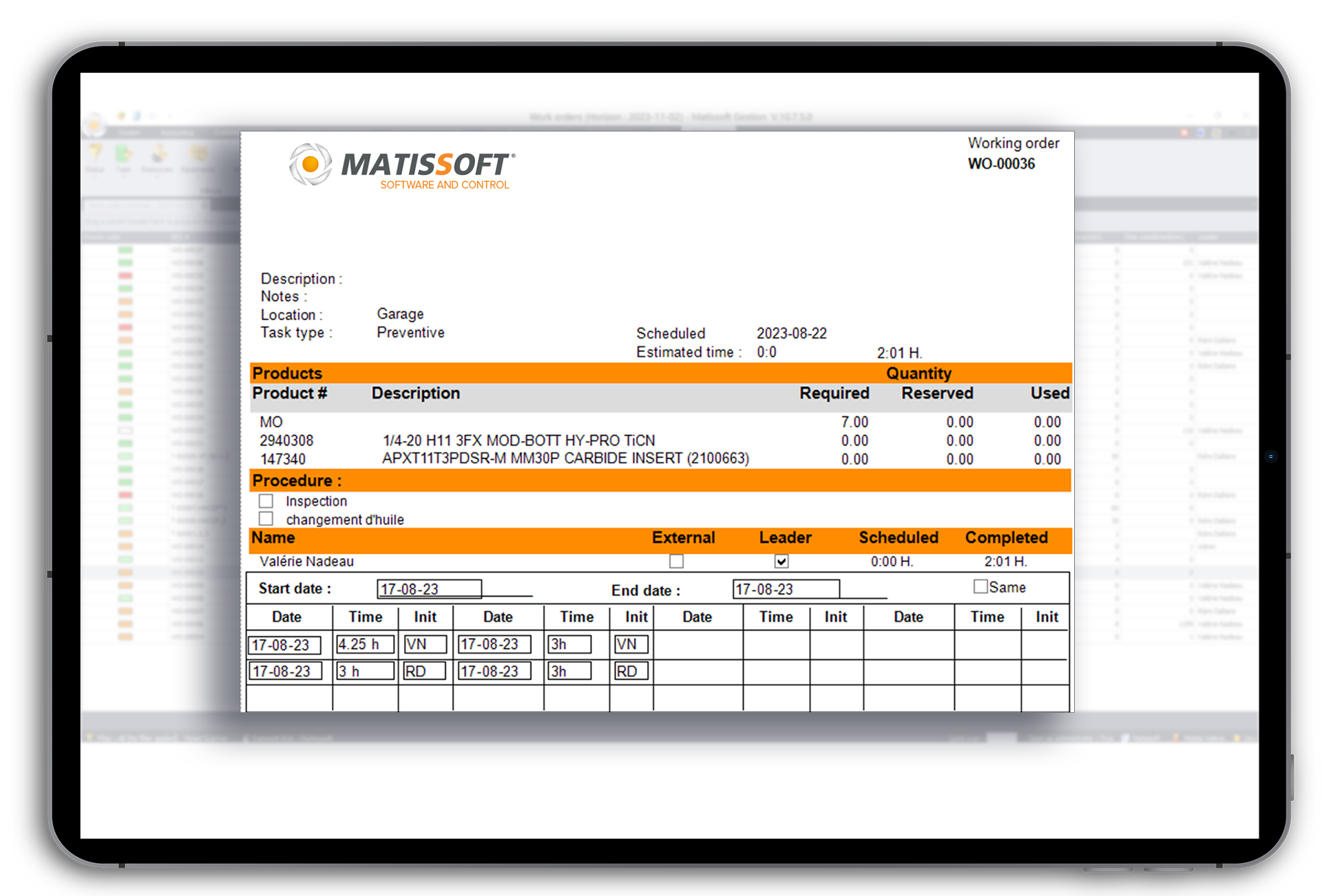

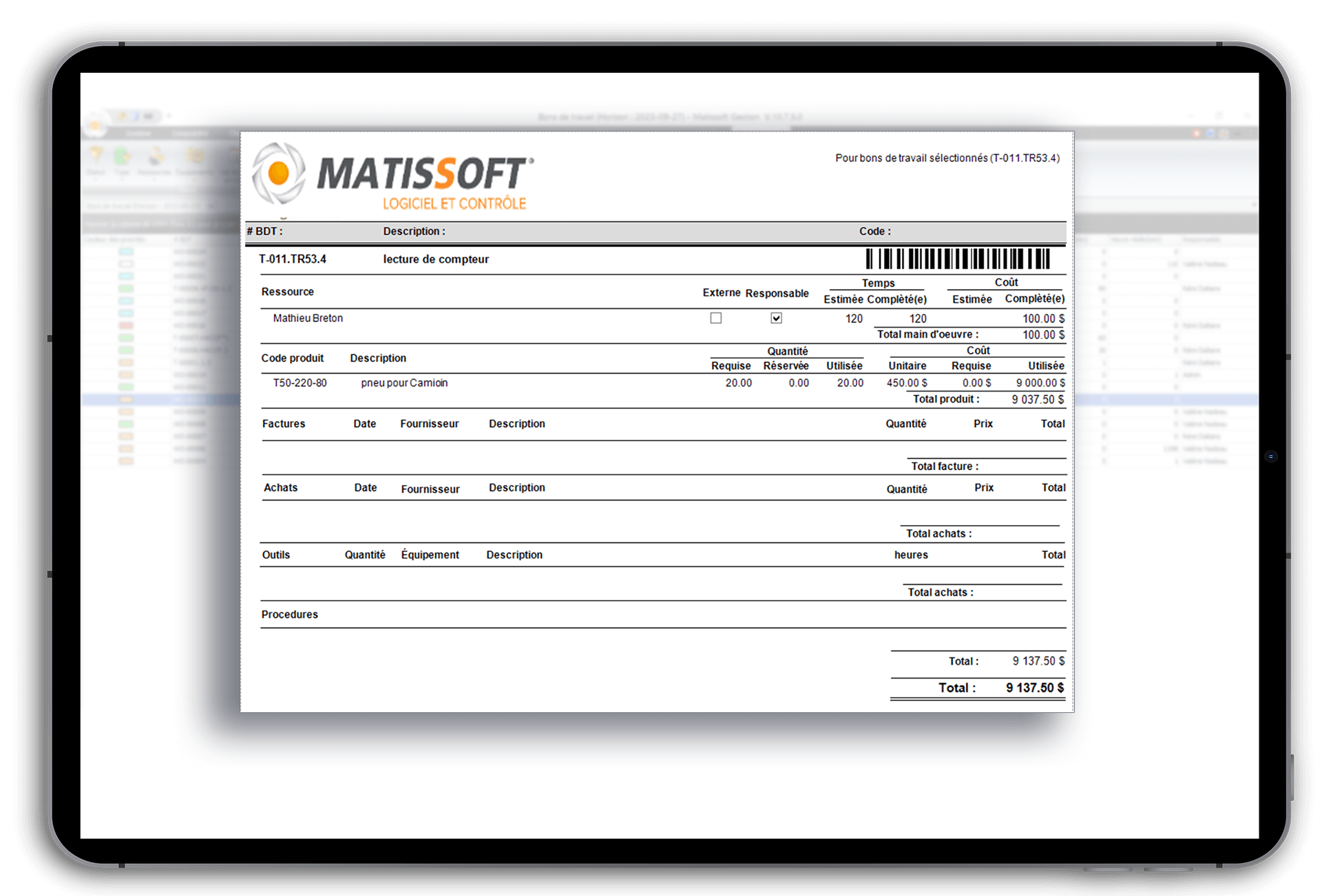

Maintenance Module

Our maintenance module will simplify the daily monitoring and planning of HACCP procedures, and of the complete maintenance of your equipment, buildings and rolling stock.

- Maintenance teams’ time management

- Inspection and planning of equipment

- Implementation of HACCP and BPM procedures

- Fleet of vehicles, buildings, computer equipment, etc.

- Automatic communication with the counters of your manual, virtual or automatic equipment (communicating with your equipment)

- Possibility of invoicing works to your other companies

- Possibility of analysis of maintenance teams’ productivity

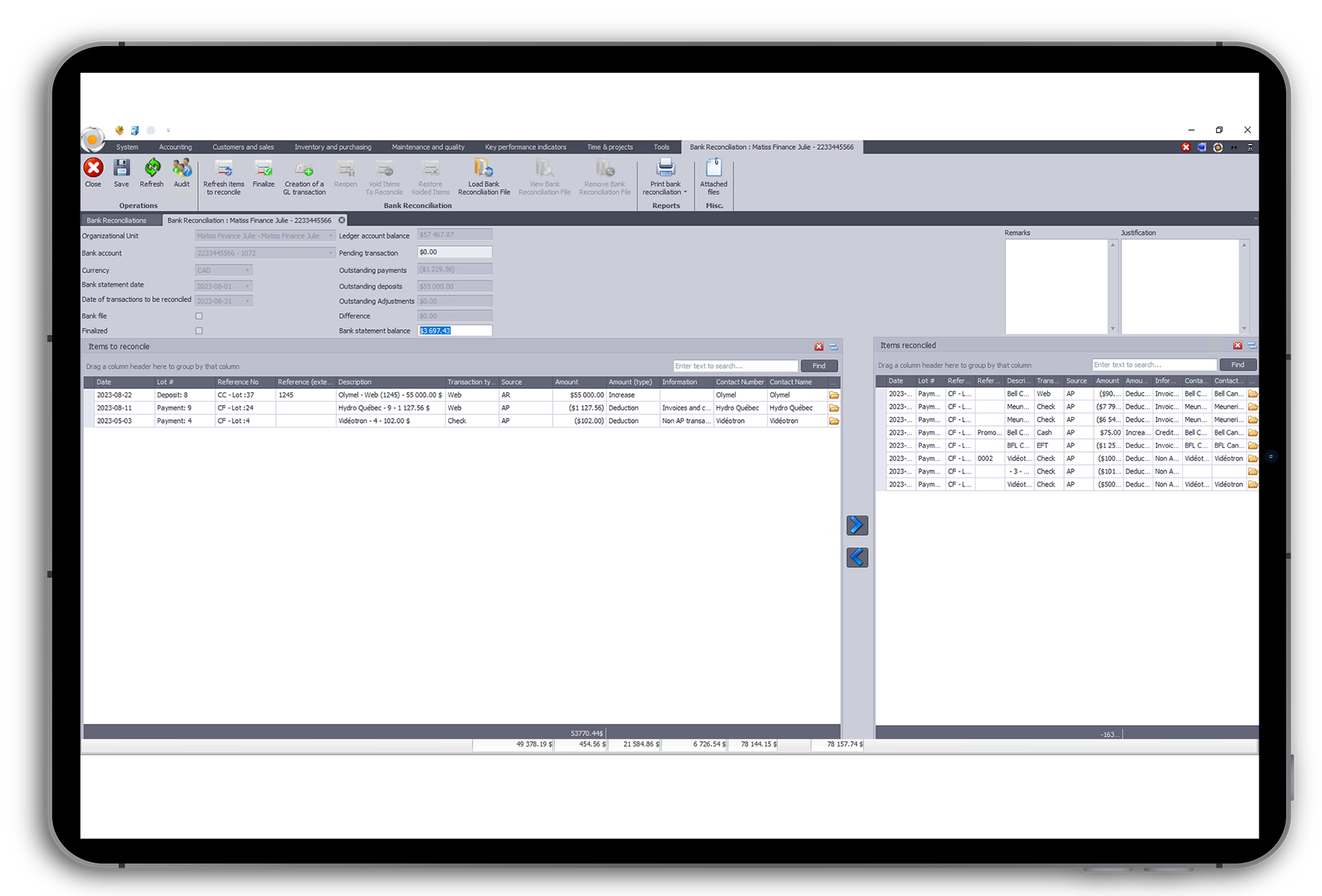

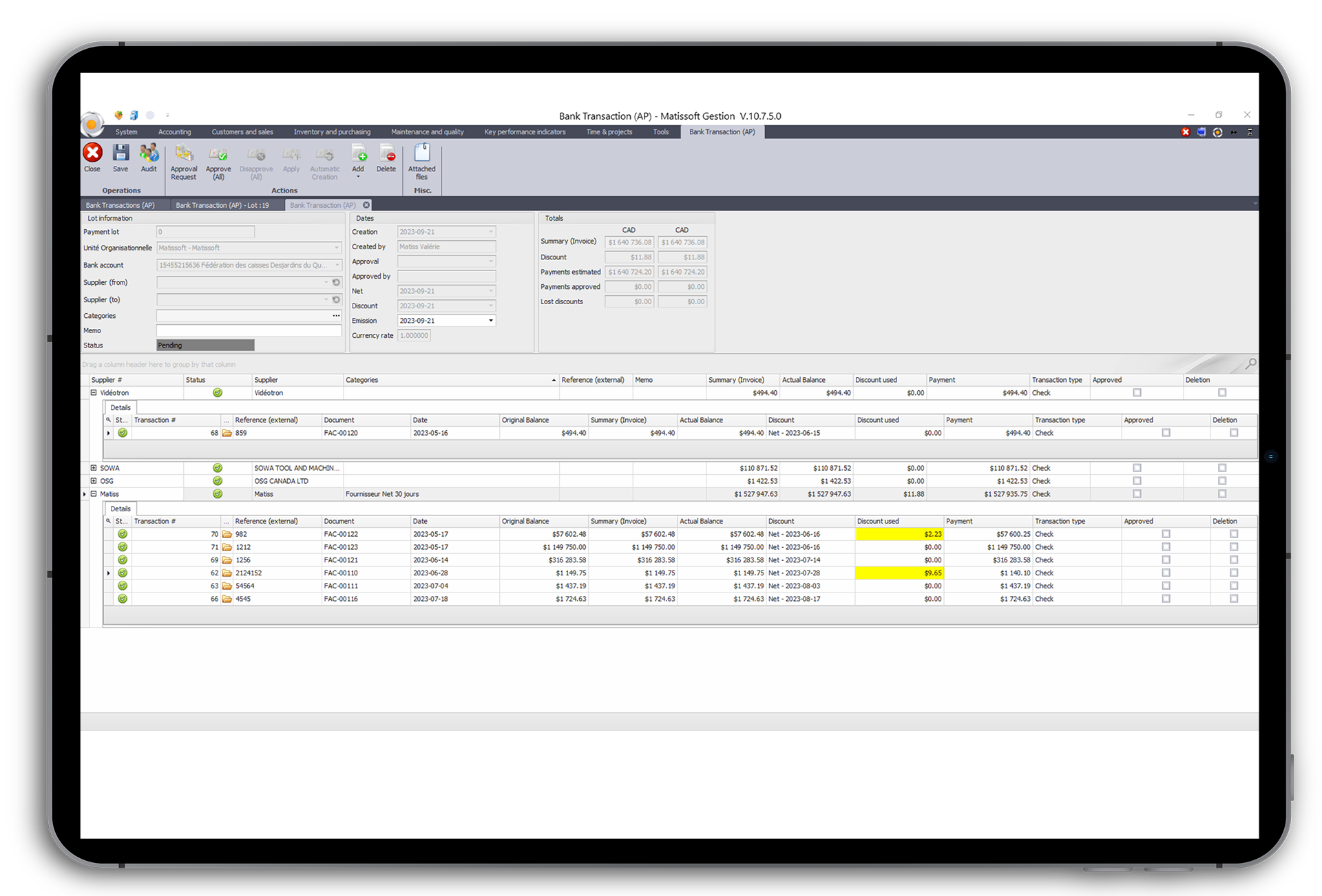

Finance Module

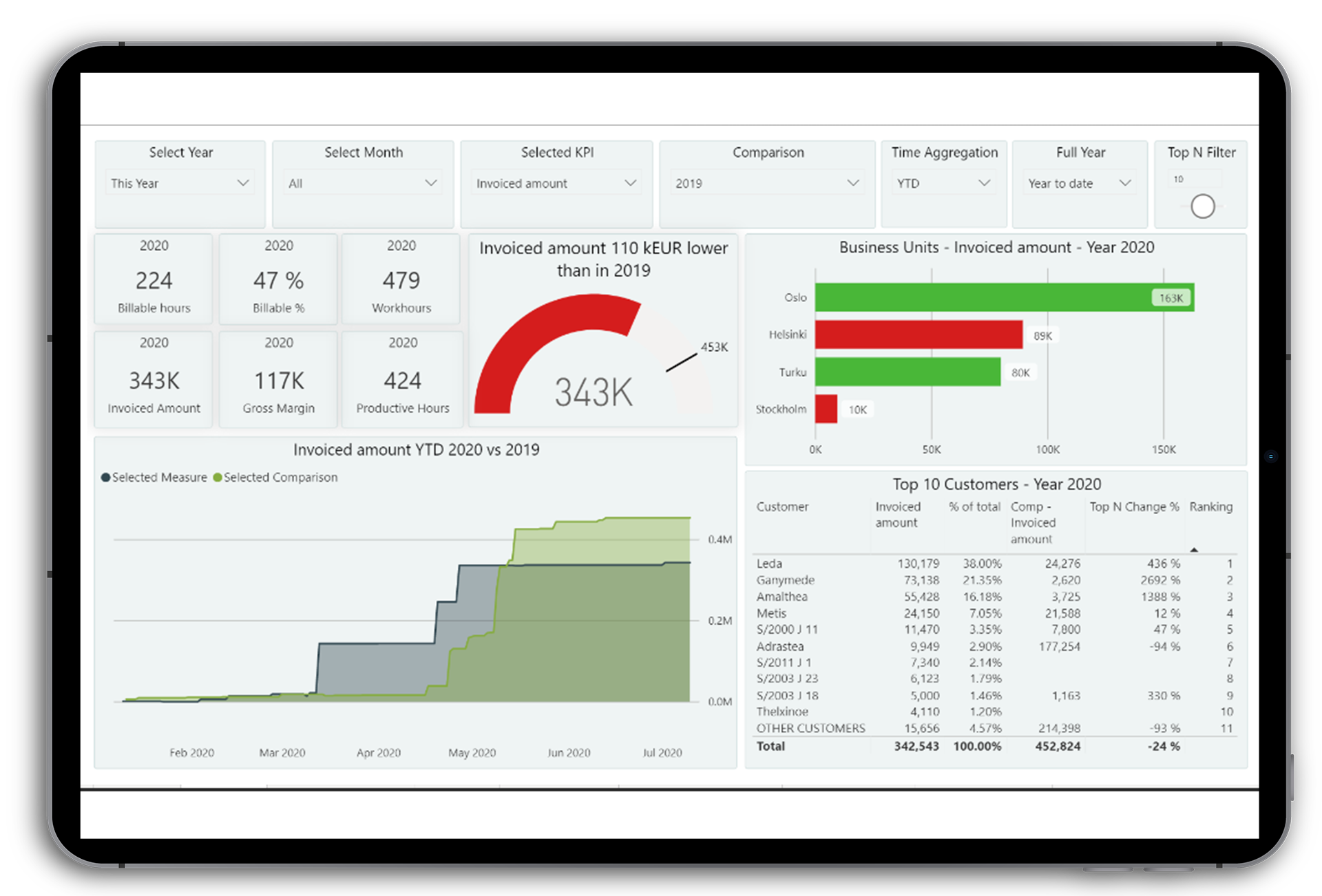

Our finance module is your key to obtaining real performance indicators that are adapted to your agricultural reality:

- Financial management of your livestock

- Daily automatic reports (KPIs)

- Consolidated financial statements with possible data mining

- Multiple and comparative budgets

- A general ledger, accounts payable and receivable

- Possibility of recurring entries for end of month presentation

- Time and approval management

- Bank reconciliation, electronic payment (TFE and PPA)

- Automatic interbusiness entry

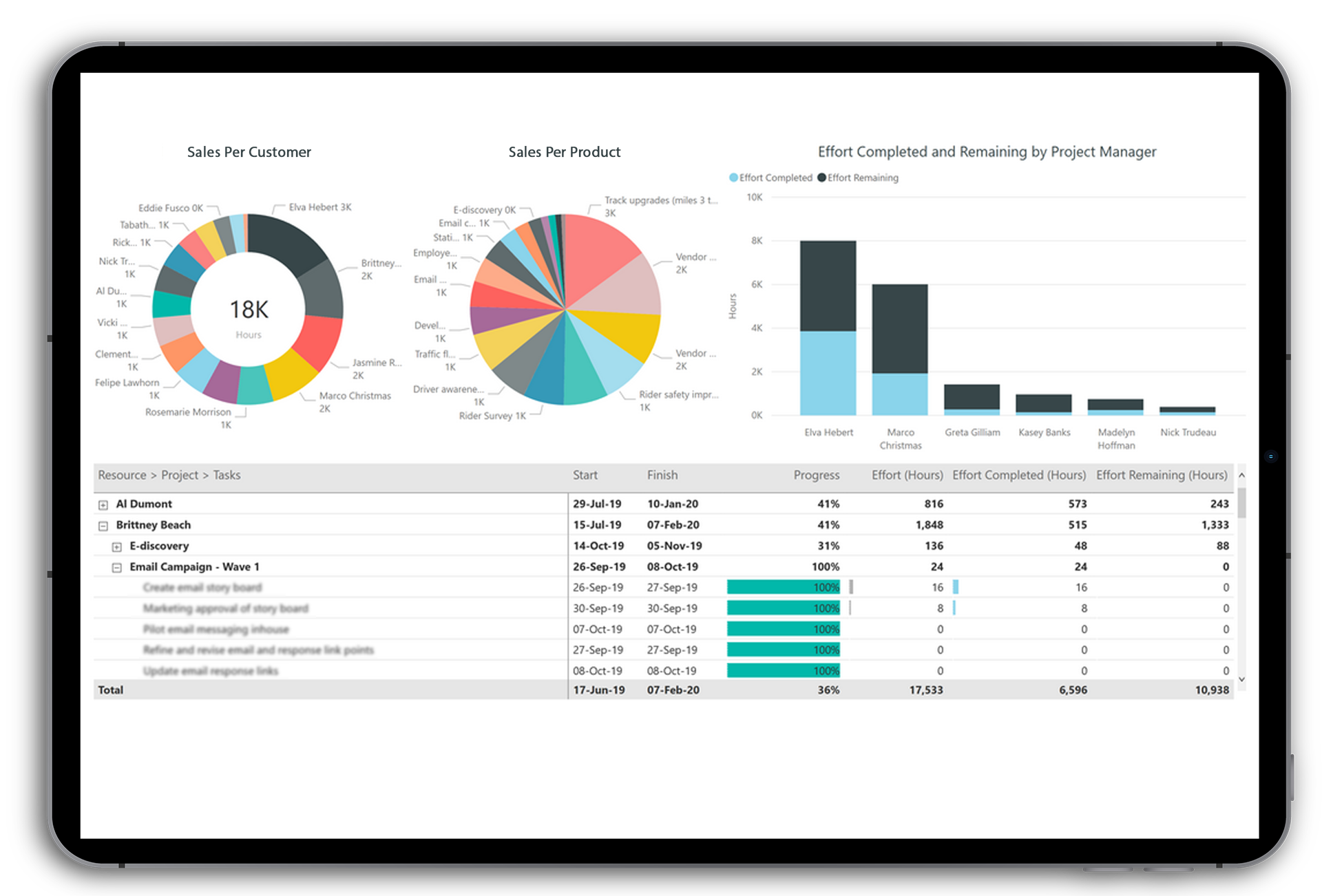

Data Warehouse Module

Centralizing all your data in a cloud solution, such as Matissoft’s data warehouse, will enable you to cross-reference information data from various systems in a secure manner without any risk to your operations.

- Accessibility to decision-making information on computers, cell phones or tablets

- Cross-referencing and data mining between modules

- Systemic traceability: comparative data

- Self-learning algorithm

- Personalized dashboard and notifications

- Performance indicators

- Progress report: clients and utilization

- Security and confidentiality of data

I use the Matissoft Finance, Business Management, Maintenance, Grain Management and Process Control software package. I recently contacted Matissoft to inform them that I was the victim of a cyber virus. Thankfully, the team acted quickly and helped to unblock the system and get operations back up and running in no time! I am highly satisfied by the professionalism and availability of their staff. I applaud their excellent work.

Executive Director